Deposition and characterization of FM core/AFM shell nanoparticles in various matrixes

- FM Fe and Co NPs were embedded in non-magnetic matrixes such as Al2O3

- The effect of deposition gas nature/pressure and post deposition oxygen pressure on NP dimensions, structure, composition and magnetic properties was studied

- For practical data storage applications, small (˞ 2 nm) NPs must be separated and partially oxidized. This was efficiently obtained by vacuum deposition and post deposition oxidation.

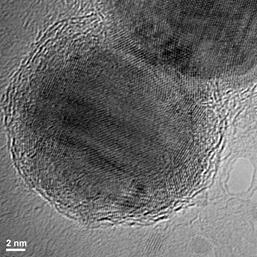

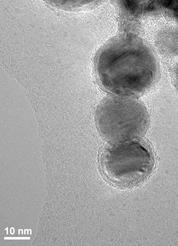

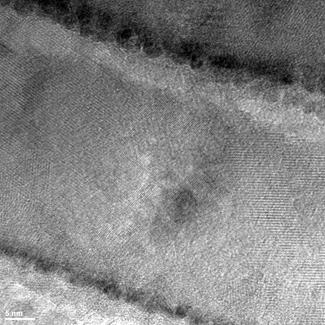

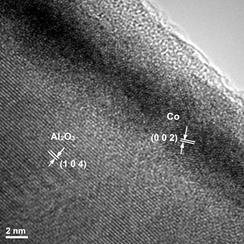

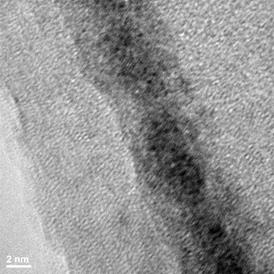

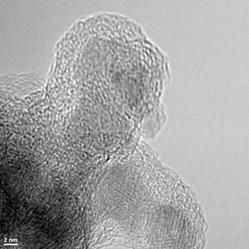

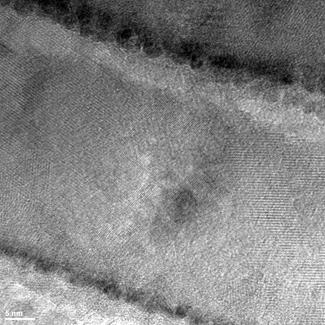

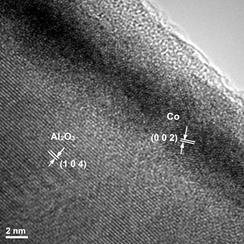

Cross-section TEM image revealing the presence of metal Co core/Co oxide shell NPs embedded in a non-magnetic Al2O3 matrix

- Both core-shell NPs and elongated FM NPs surrounded by an AFM or ferromagnetic area and embedded in a non-magnetic matrix have a higher blocking temperature due to exchange bias, as well as larger magnetization

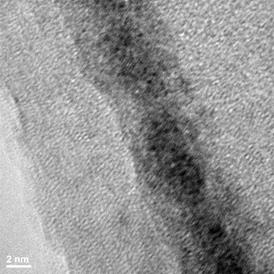

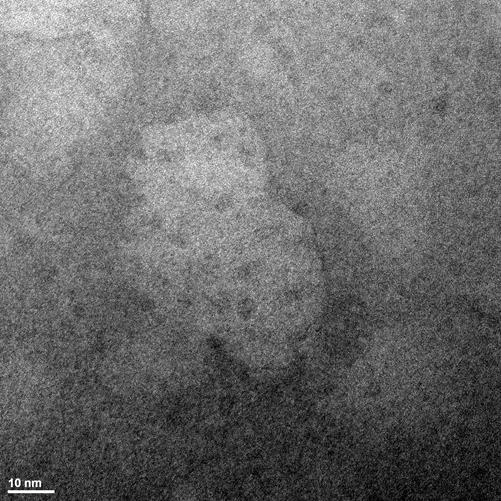

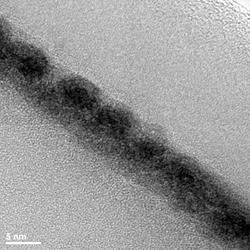

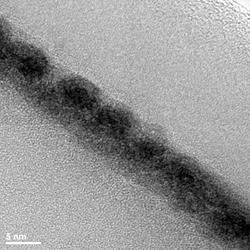

TEM of elongated Co NPs surrounded by Co oxide and embedded in an Al2O3 matrix obtained by deposition in 10-5 mbar oxygen

- Matrixes must be chosen to ensure formation of separate NPs on surface; this is obtained for Al2O3 , which also prevents further oxidation of NP surface

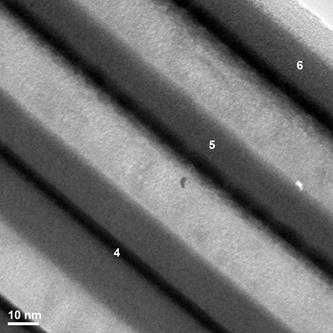

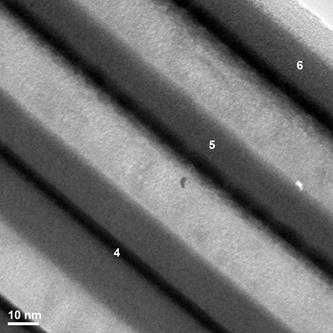

Layers of Co (black) deposited on Cr2O3 (dark gray) and Al2O3 (light gray). The former matrix leads to continuous films; the latter leads to separate NPs. Co obtained with the same number of pulses in all cases

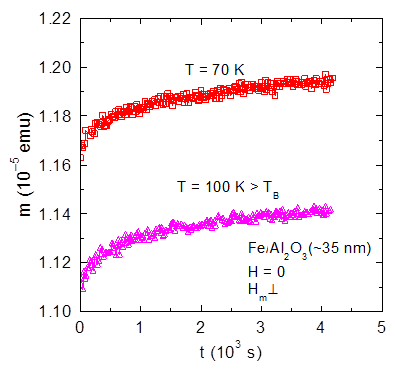

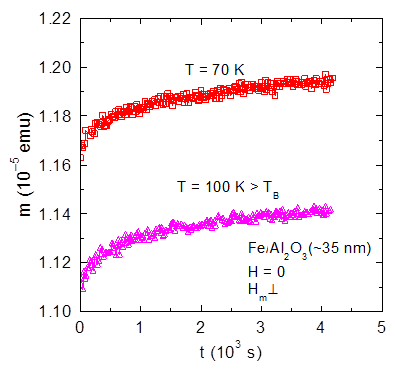

- Superferromagnetic (SFM) behavior was revealed using time relaxation of the magnetization in nanocomposites with large separation (35 nm) between rows of Fe NPs and in perpendicular applied field H

Remnant magnetization m(T) for T > TB in Fe/Al2O3 nanocomposites with a large separation between Fe NP layers, showing an increase with t; this indicates the presence of a memory effect characteristic for SFM

Deposition and characterization of nanoparticles (NPs) with a

Ferromagnetic (FM) core - Antiferromagnetic (AFM)/ferrimagnetic

shell structure

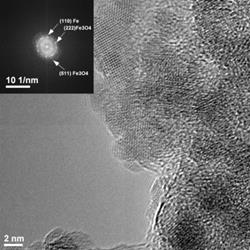

- Nanoparticles having a Co/CoO, Ni/NiO and Fe/Fe3O4 core-shell structure were obtained by PLD in a controlled atmosphere in various experimental conditions.

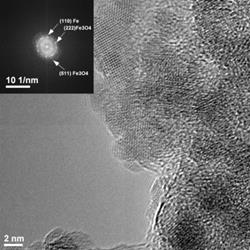

Fe nanopowders obtained by PLD in a He atmosphere and oxidized post-deposition into a FM core-ferrimagnetic shell structure, as evidenced by SAD and EDX analysis.

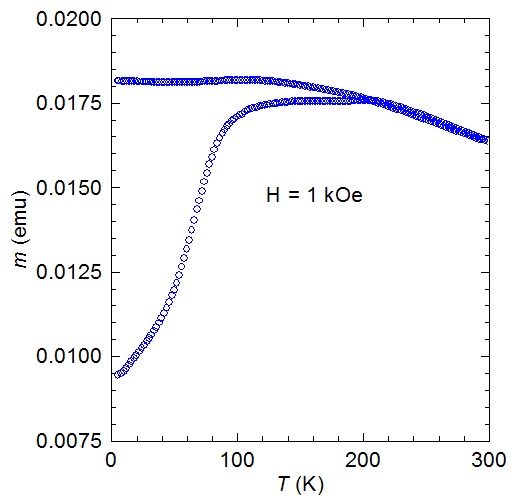

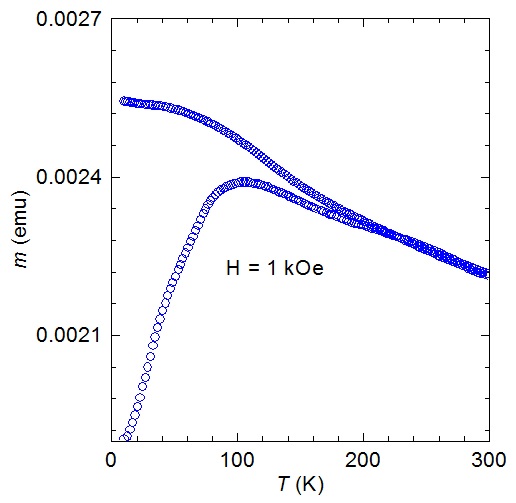

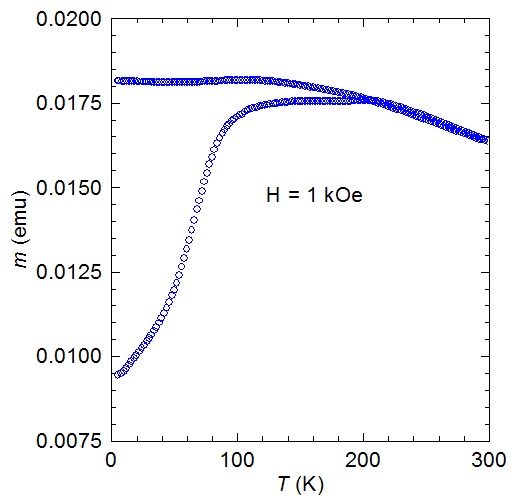

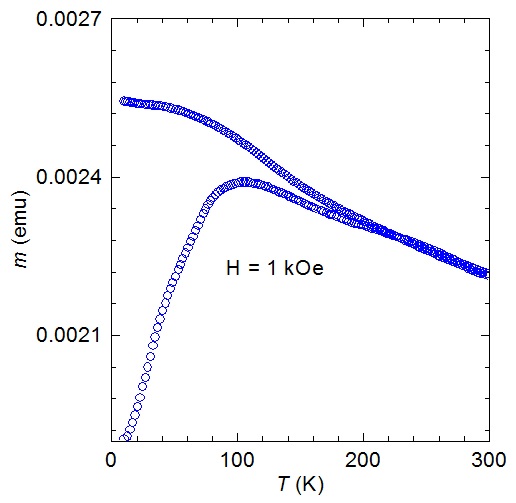

ZFC/FC curves of Fe nanopowders obtained at two different deposition pressures. Experimental conditions leading to higher blocking temperatures, as determined from ZFC/FC curves, have led to optimization of deposition and post-deposition parameters.

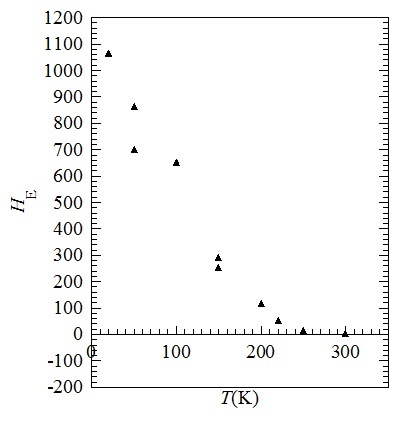

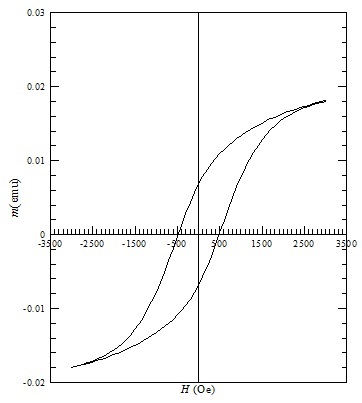

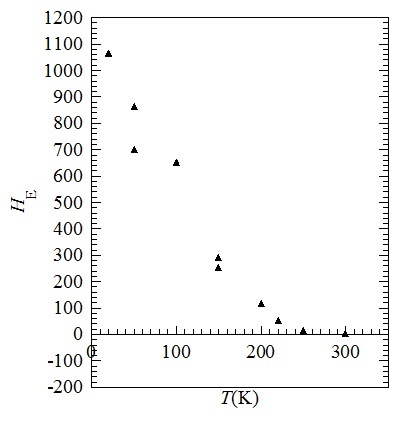

- The exchange bias for different temperatures was determined from the M(H) hysteresis curves. The exchange bias decreases with increasing temperature and disappears at about 250K for all experimental conditions investigated:

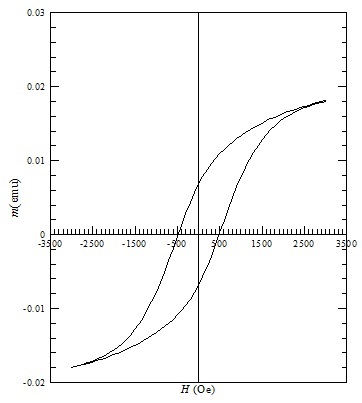

- Although exchange bias is absent, hysteresis is still present even at 300 K, probably due to the distribution of NP dimensions, which includes large particles:

Hysteresis of typical Co/CoO core-shell structure nanopowders at 300K.

- The use of ultrashort laser pulses (ps duration) leads to improved magnetic properties of the core-shell nanopowders.

- Measurements of the magnetic properties have indicated an increase of TB and of the magnetic moment m for the core-shell structures which favorize exchange bias. Such structures are obtained by deposition in an inert gas atmosphere, followed by controlled oxidation with formation of the oxide shell, which ensures the interface at which the exchange bias interaction occurs.

Deposition and characterization of Ferromagnetic (FM) nanoparticles (NPs) in Antiferromagnetic (AFM) and Ferrimagnetic matrixes by succesive laser deposition

- FM NPs (Fe, Co, Ni) are embedded in AFM (CoO, Cr2O3, NiO) or ferrimagnetic (Fe3O4) matrixes

- In order to ascertain the relative importance of exchange bias in the magnetic properties of the nanocomposites, FM NPs are also embedded in non-magnetic matrixes such as Al2O3.

- Various material combinations and structures are being explored, taking advantage of the wider range of possibilities these types of structures allow, compared to core-shell structures.

- The resulting nanocomposite films (NCs) have been characterized using high-resolution electron microscopy (SEM, TEM, EDS, EDAX)

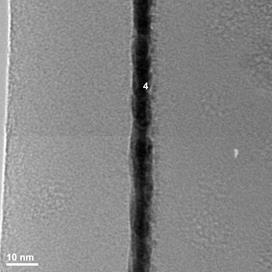

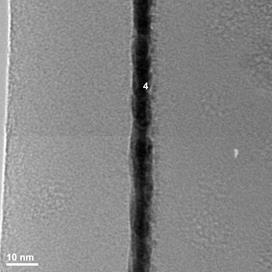

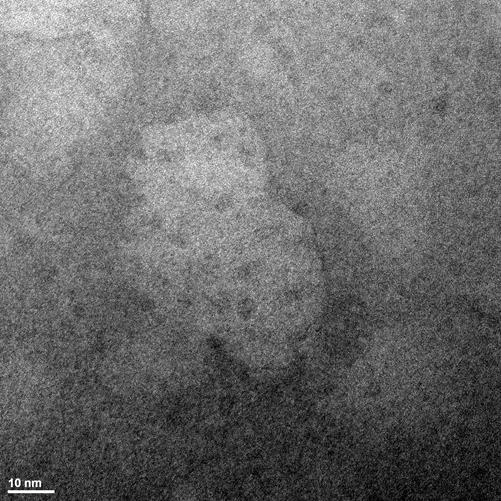

Cross-section TEM image of Fe/Al2O3 nanocomposite films, indicating the presence of NPs with the diameter of ~2.5 nm, in a single row for each succession, placed between ~35 nm-thick Al2O3 rows. The overall film thickness is of 420 nm. The 2-dimensional arrangement of NPs between the oxide layers is visible.

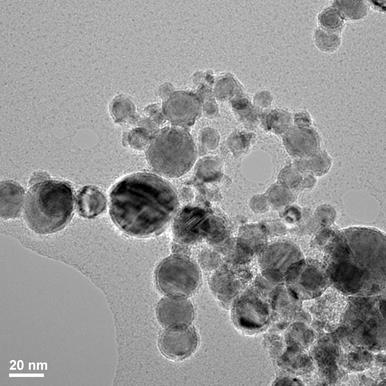

- The mean characteristic size of the NPs is well within the range of single domain NPs

TEM image of the surface of a nanocomposite Fe/Al2O3 film, indicating the spherical shape of the NPs and the relatively large distance between them, which should not favour inter-particle interactions. The uniform particle density across the surface of the film is visible.

- The composites hava a relatively low metal NP concentration, where interparticle interactions are weak. The effect of interparticle interactions is currently being analyzed, since it affects the essential magnetic properties of the NPs.

- DC magnetic measurements were performed using a commercial Quantum Design MPMS system, with the magnet system in persistent mode and H oriented parallel to the substrate.

- Magnetic properties of the nanocomposite films have also been determined using an ultrasensitive SQUID magnetometer.

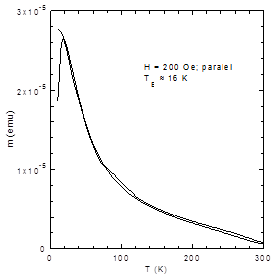

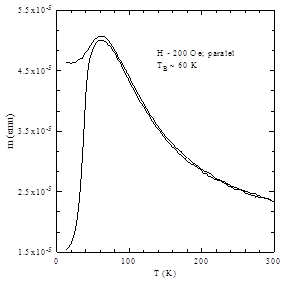

Main panel: Characteristic T variation of the magnetic moment m measured in zero-field cooling (zfc) and field cooling (fc) conditions for Fe/Al2O3 nanocomposite films for H well below the switching field (H = 50 Oe, and 200 Oe). The mean blocking temperature TB corresponds to the maximum of the T derivative of Dm = mzfc – mfc, as shown in the inset for H = 200 Oe.

- Due to significant NP dispersion, it is better to determine a mean blocking temperature TB, defined as the T value corresponding to the maximum in the temperature derivative of Dm = mzfc – mfc, as in the inset of the figure.

- The NCs behave like FMs below the blocking temperature, with a coercitive field of the order of 102 Oe.

- Well above TB, the thermal excitation induces rapid fluctuations of the particle moment m as compared with the observation (measuring) time tm, and m can be described by an effective paramagnetic model. The fit of the m(H) curve with the Langevin function for superparamagnetic (SPM) particles leads to NP dimensions which coincide with TEM results.

- The effect of deposition and materials parameters on the mean blocking temperature (as defined above) is being studied, with the aim of optimizing the applications-related properties of the structures.

Activity report 2014

The activities undertaken during the 2014 research stage included the deposition, using succesive laser deposition, of nanocomposites consisting in Fe and Co ferromagnetic (FM) nanoparticles (NP) embedded in non-magnetic matrix materials. The NPs either had a FM core/AFM or ferrimagnetic shell structure, or consisted in FM NPs surrounded by AFM or ferrimagnetic regions, depending on the gas parameters.

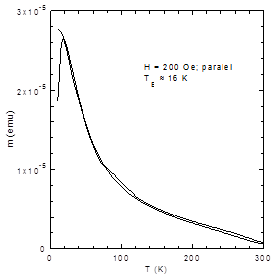

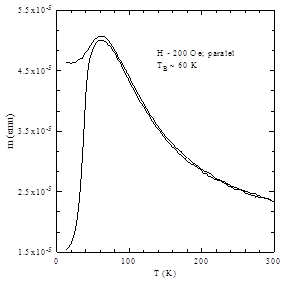

We studied the effect of the nature and pressure of the gas used during deposition or post-deposition. At low pressures (10-7 – 10-6 mbar oxygen), the NPs are spherical, have small dimensions (2-3 nm) and are well separated. The NPs are completely metallic and have a superparamagnetic (SPM) behavior with a relatively low blocking temperature TB (16K). With the increase of the deposition pressure, the NP dimensions increase (both in an oxidizing gas atmosphere and in an inert one); in the case of deposition in oxygen the degree of oxidation increases as well, from partial to complete oxidation. For depositions in 10-5 mbar oxygen, a partial oxidation of the metallic NPs occurs, leading to an FM/AFM or FM/ferrimagnet interface which ensures exchange bias. In the case of vacuum deposition and post-deposition oxidation up to 1 atm oxygen, spherical core/shell NP shaving small dimensions are generated in a non-magnetic matrix. For both of these cases of partial NP oxidation, the blocking temperature is much bigger (60 K in the case of post-deposition oxidation). It is worth mentioning that improved magnetic properties do not necessarily imply the existence of core/shell type NPs; the existence of an interface between NPs elongated in one direction and an irregular surrounding AFM or ferrimagnetic zone having a similar effect on the magnetic properties.

These conclusions have important practical implications : in order to obtain nanocomposites (NCs) which can be used in high density data storage systems, it is important for the NPs to be separated and partially oxidized at the surface. Vacuum deposition followed by post-deposition oxidation ensures both small NP dimensions (2-3 nm) and a separation between them, which is necessary in order to ensure independent accessing of the memory bits (read/write). Unlike the nanopowders previously obtained in our experiments, the embedding of core/shell NPs in matrixes prevents NP agglomeration, maintaining small, nm order dimensions. The use of non-magnetic matrixes with a higher oxygen affinity (such as is the case for the Al in Al2O3) allows the limitation of the oxidation region of the FM material in NPs, unlike the FM metal oxide matrix.

As far as the interface is concerned, the matrix material should lead to the organization of FM metals on its surface as separated NPs with a clear structure, as is the case of Al2O3 matrixes. For each matrix, the number of ablation pulses must be optimized in order to prevent the organization of metals in thin films, leading instead to separate NPs.

The study of the relaxation of the magnetic moment of 2-3 nm spherical Fe NPs embedded in relatively thick/thin (35 nm/3nm) Al2O3 matrix layers revealed collective effects and interaction between NPs. In the case of large separation between NP layers and perpendicular magnetic field H (on the NP layers), interactions appear between the NP components, which do not permit independent accessing (read/write) of the magnetic state, since the magnetic state of one NP is influenced by that of other ones.

All of the objectives of the 2014 research stage were reached, and the conditions for the next stage are met, which deals with the effects of thermal treatments on the nanocomposites previously obtained.

Dissemination of the research results was made through publication of papers in Physica C 500 (2014), p. 40-43 and Journal of Superconductivity and Novel Magnetism, appearing on-line in august 2014 (DOI: 10.1007/s10948-014-2652-7), both including acknowledgements for financial support. Dissemination was also ensured through chapter 9 in „Size effects in Nanostructures”, Springer Series in Material Science 205 (2014), ISSN 0933-033x; which includes acknowledgements. A national patent request was submitted to OSIM (registration no. A/00776 dated 20.10.2014), the inventors being D. Miu, C. Sima, I. Nicolae, C. Viespe and I. Nistorescu. Two oral communications were made at the ICCE-22 International Conference in Malta (July 13-19, 2014), which also includes acknowledgements for financing. Finally, a paper was submitted to Journal of Applied Physics (Manuscript # JR14-11733), with acknowledgements, authors D. Miu, S. Jinga, B. Vasile, L. Miu.

a) b)

a) Co NPs deposited in vacuum (670 pulses) onto alumina and post-deposition oxidized by introducing oxygen in the deposition chamber with 1000 sccm up to 1 atm. b) Analysis of the composition of NC components.

a) b)

a) ZFC/FC magnetization curves for nanocomposites obtained by depositing Fe NPs onto a Al2O3 matrix in vacuum; the blocking temperature is 16 K. b) ZFC/FC curves for nanocomposites obtained by depositing Fe NPs in 10-5 mbar O2 in an Al2O3 matrix; the blocking temperature is about 60 K.

|